Patrick's SMART Partnership progress with 3 Sixty

In May 2024, PDR started a SMART Partnership with Cardiff-based creative studio, 3 Sixty. Funded by Welsh Government, a SMART Partnership is a knowledge transfer programme unique to Wales – a three-way partnership between a research organisation like PDR, a Wales-based business and an associate who is based within the business to drive forward a project that will have a long-term positive impact. We spoke to our SMART Partnership associate, Patrick Richards, and his supervisor here at PDR, Katie Beverley, to find out more about the project, SMART Partnerships and other knowledge transfer opportunities.

What was the initial aim of your role at 3 Sixty

Patrick: 3 Sixty is a fast-paced working environment full of people working incredibly hard to meet tough deadlines. The premise of me being there as a SMART designer is to take on those challenges facing the company that they don’t have the immediate resource to deal with. My project is all about improving the circularity and sustainability of lightboxes, which form a key part of 3 Sixty’s business. Lightboxes are a common piece of retail visual merchandising, normally built bespoke for each store design to enhance the visibility of a graphic or poster by having it lit from behind.

Katie: At PDR, we’ve got over twenty years of sustainable design knowledge that we can make use of in a project like this, but if we were to do the work ourselves, it wouldn’t build the capacity in 3 Sixty that will be needed for a new product or service offer around lightboxes. Patrick’s role truly is the magic ingredient – he has excellent product design skills and a real interest in sustainable design. He works within 3 Sixty so understands the business context and can bring that to the discussions we have about sustainable and circular product design.

How has the project’s challenge developed during your time there?

Katie: So, one of the first things we did was build a preliminary model of the product and use readily available data to understand where the biggest environmental impacts are throughout its life cycle. From that, we realised that one of the product components we hadn’t even talked about was having a big impact on sustainability performance, so what we do about that is now built into the design brief.

We also want to demonstrate the value that circular economy thinking brings to a business. We’ve been trying out some different metrics that have led us to think about different materials, designs and services – that’s really broadened the number of possible products and services that 3 Sixty can explore.

What possible solutions have you arrived at?

Patrick: So far, I’ve come up with loads of concepts. We can’t really talk about the specifics of them, but I’m in the middle of the prototyping stage at the minute so just trying to test which of the concepts could ever work.

Katie: At the moment, Patrick is being a typical product designer and focusing on the making! What I’m trying to encourage him to remember with each prototype, though, is that the business model that creates the circular value (which is usually a combination of product and service) drives the product design. So, as well as prototypes of products, we’ve also developed prototypes of ‘value propositions’ - short descriptions of the product and service combinations that create value for customers – to test in our next phase of work.

How has working with Katie and PDR helped you so far?

Patrick: Learning from everyone at PDR has been great, there’s such a wealth of knowledge and experience in the building. Katie Beverley has been great, what she doesn’t know about the circular economy isn’t worth knowing.

What are the next steps in the project?

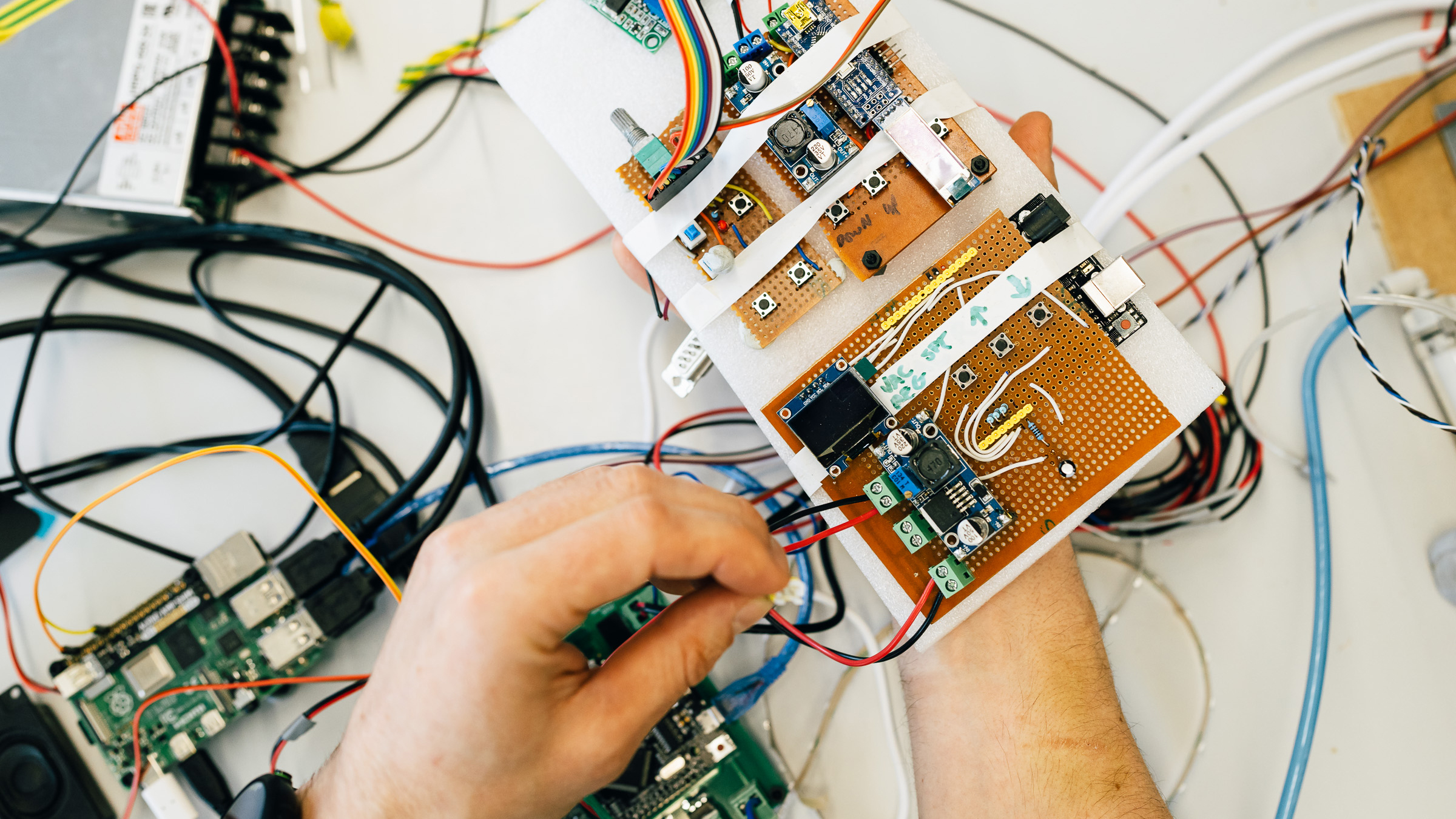

Patrick: It’s all about testing and iterating as many prototypes as possible, so I’ll been spending more and more time in FabLab. The facilities there are great: woodworking facilities, laser cutters, loads of 3D Printers and the people there are really helpful. It’s always the most enjoyable part of the project for me when you’re making and breaking prototypes.

Katie: Patrick’s in his element with the prototyping, but I’m itching to get into the user testing. We’re coming up with some new products, but also new services and it’s going to be about developing a testing protocol that allows us to test out both with real users.

What would you say to another company who was thinking about whether a knowledge transfer project was for them?

Katie: I’d say, ‘Do it!’. They’re such a great way of building capacity for innovation in an organisation and there are benefits to both business and research partner. In the case of knowledge transfer mechanisms like SMART Partnerships, (and Knowledge Transfer Partnerships, which are UK Government funded projects that can run for up to three years). Many companies find that when the partnership comes to an end, that they’re not ready to let their associate go... so it can be a great way of recruiting someone who will bring real long-term value to the firm.

Patrick: I’d tell any graduate to look out for SMART Partnerships or any knowledge transfer project, I think it’s an amazing thing to do at the start of your career. You get to experience and learn from two different companies, and you’re given the responsibility and time to lead your own project which is an incredible opportunity, and there is a lot of support around you including a training budget to grow your skills. I’ve already learnt so much during the project and we’re not even halfway through yet!

Interested in learning more about SMART Partnerships? Find out more about how we work with them here.